AMFOR: Additive Manufacturing for Casting Models

The project aims to analyse the manufacture of models for the Lost Foam and Lost Wax casting processes, using SLA 3D printing technology and the recently introduced innovative "Castables" materials.

The project aims to demonstrate the advantages of 3D printing technology for the manufacture of casting models (lost wax/lost foam) compared to traditional methods. The results obtained will be of great value to the foundry and additive manufacturing sector.

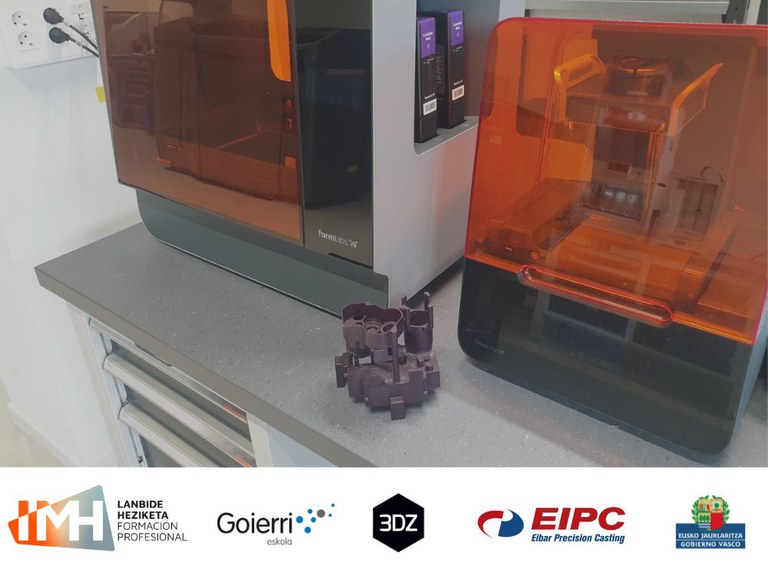

At the IMH Campus Integrated Vocational Training Centre, resin models were produced using SLA 3D printing technology. The resin parts have been used to make the plaster moulds for the foundry at Goierri Eskola. The material to be cast is aluminium.

Eibar Precision Casting (EiPC) is interested in the project to see if the resin printing technology can be used in practice in their processes for the manufacture of lost wax models. In turn, 3DZ provides the technology for SLA 3D printers.

A Vice-Ministry project in which the necessary steps are being taken to achieve the proposed results.

Project participants: CPES DEL GOIERRI BHIP - (project leader), CIFP IMH LHII, AMPO (collaborating company).