Successful cases

Examples of projects carried out by the IMH Centre for Applied Innovation

Automated transfer of parts

In this case, for stamping processes, we have developed the automatic transfer from post to post of a reference for the automotive industry, manufactured by cold stamping; all synchronized with the rate of the press.

Manufacture of the first set

Manufacture of the first set of a new concept of racing bicycle crankset with its own patent, as well as the definition of the machining process for its industrialization.

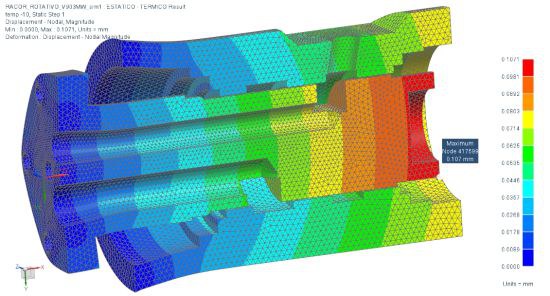

Finite element simulation

A company works on the design, manufacture and marketing of machine components (cylinders and hydraulic equipment). The evaluation of new designs is carried out by means of finite element simulations, as well as to design component improvements.

Definition of a new process

A manufacturing company has the possibility to obtain an order to produce structures for a world leader in the aeronautical sector, but one of the conditions is friction welding. This company has never used this system. After analysing patents and suppliers, the welding tools were designed and after machining the tool in four geometric configurations (40 in the first phase), welding tests were carried out on the milling machine until a standardised process was achieved.

Improving the process

The customer needs to improve the manufacturing process of a part. In addition to labour, the process has 9 operations to be performed on 4 different machines. After drawing the image in 3D and developing the CAM program, an investigation has been carried out, with the aim of reducing the process to 6 operations carried out on a single 5-axis machine (a single bundle) and reducing it to a final cut by electro-erosion. The cost of production has been reduced by 65%.